china heavy duty slurry pump manufacturer

Latest articles

- Hydraulic efficiency is as important as the material, as efficiency is related to wear. The swept-back design of the impeller blades minimises the separation of solids from the carrying fluid, resulting in a more uniform flow. This results in a slower wear rate.

china heavy duty slurry pump manufacturer...

china heavy duty slurry pump manufacturer 【china heavy duty slurry pump manufacturer】

Read MoreSlurry pipe diameter.

china heavy duty slurry pump manufacturer...

china heavy duty slurry pump manufacturer 【china heavy duty slurry pump manufacturer】

Read MoreWhen pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

china heavy duty slurry pump manufacturer...

china heavy duty slurry pump manufacturer 【china heavy duty slurry pump manufacturer】

Read MoreFewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

china heavy duty slurry pump manufacturer...

china heavy duty slurry pump manufacturer 【china heavy duty slurry pump manufacturer】

Read MoreFor example.

china heavy duty slurry pump manufacturer...

china heavy duty slurry pump manufacturer 【china heavy duty slurry pump manufacturer】

Read MoreThere is a science behind the design of a , slurry pump, , based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

china heavy duty slurry pump manufacturer...

china heavy duty slurry pump manufacturer 【china heavy duty slurry pump manufacturer】

Read MoreSlurry Pump Impeller Size

china heavy duty slurry pump manufacturer...

china heavy duty slurry pump manufacturer 【china heavy duty slurry pump manufacturer】

Read MoreWhat we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. , Slurry pumps, are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

china heavy duty slurry pump manufacturer...

china heavy duty slurry pump manufacturer 【china heavy duty slurry pump manufacturer】

Read More- Keeping clean catch basins clean from solids

china heavy duty slurry pump manufacturer...

china heavy duty slurry pump manufacturer 【china heavy duty slurry pump manufacturer】

Read MoreWA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

china heavy duty slurry pump manufacturer...

china heavy duty slurry pump manufacturer 【china heavy duty slurry pump manufacturer】

Read More

Popular articles

- Slurry Pump

- To reduce wear, reduce the pump discharge pressure to the lowest possible point.

- Mud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

- If a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

- If you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

- 2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

Latest articles

-

Slurry Pump

-

The selection of a dredge or >slurry pump can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

-

Submersible Slurry Pump

-

How much solids damage can the customer tolerate?

-

Damage to slurry pumps can range from burst seals to bearings and component housings wearing out where they join, to impellers corroding due to cavitation or severe wear and so on. However, there are solutions to these problems.

-

In AIER® slurry pumps, WY & WYJ sump pump are vertical centrifugal slurry pump, submerged for transfer abrasive, coarse particles and high density slurry. When working, it needs no seal water or any kind of seal. It can work well as well when suction volume is not enough.

Links

- In automotive repairs, Diall self-fusing tape is a valuable tool for sealing hoses, fixing leaks, and protecting wires. It can withstand the heat and vibration of the engine compartment, making it a reliable choice for emergency repairs on the road. The tape is also resistant to oils and fuels, ensuring a secure seal in automotive applications.

How to use self-amalgamating tape

- />

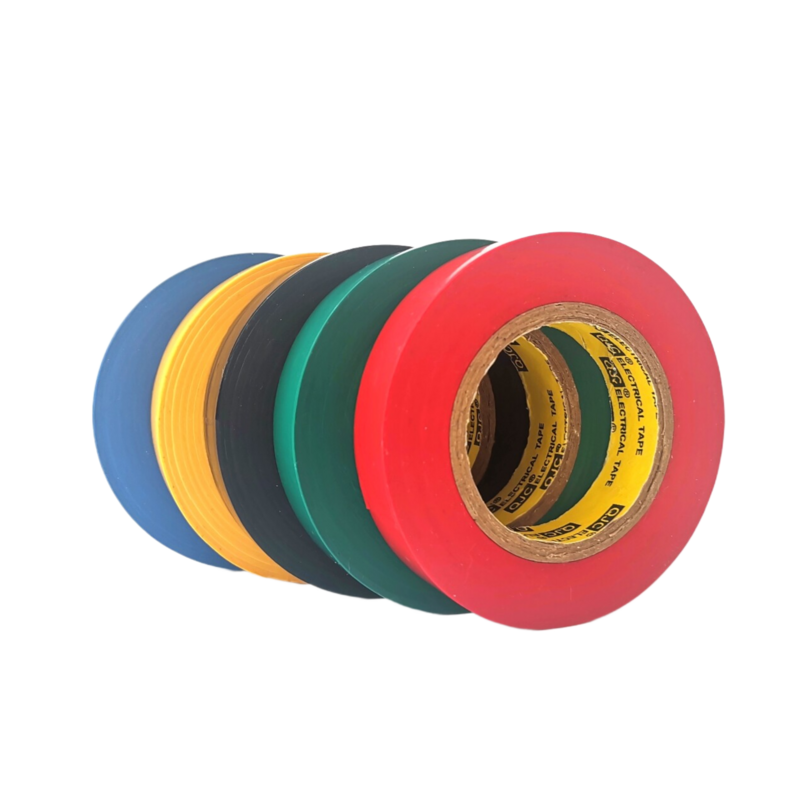

In electrical applications, white PVC insulation tape is often used for insulating wires and cables. It helps to prevent electrical shorts and protects against moisture, which can lead to corrosion and system failure. Whether encasing a repair or bundling multiple wires together, this tape ensures that connections remain safe and operational.

white pvc insulation tape

Selecting the right tape for motor connections

When it comes to maintaining the integrity of our homes and buildings, one of the most vital aspects is ensuring that leaks and moisture are effectively managed. Water damage can cause irreversible harm, leading to mold growth, structural issues, and significant repair costs. This is where premium waterproof sealants, specifically butyl rubber tape, come into play. This article explores the benefits and applications of butyl rubber tape in leakage repair, highlighting its role in preserving the longevity of structures.

3. Customization and Technical Support

It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure

It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure